TORQUE EFFICACY

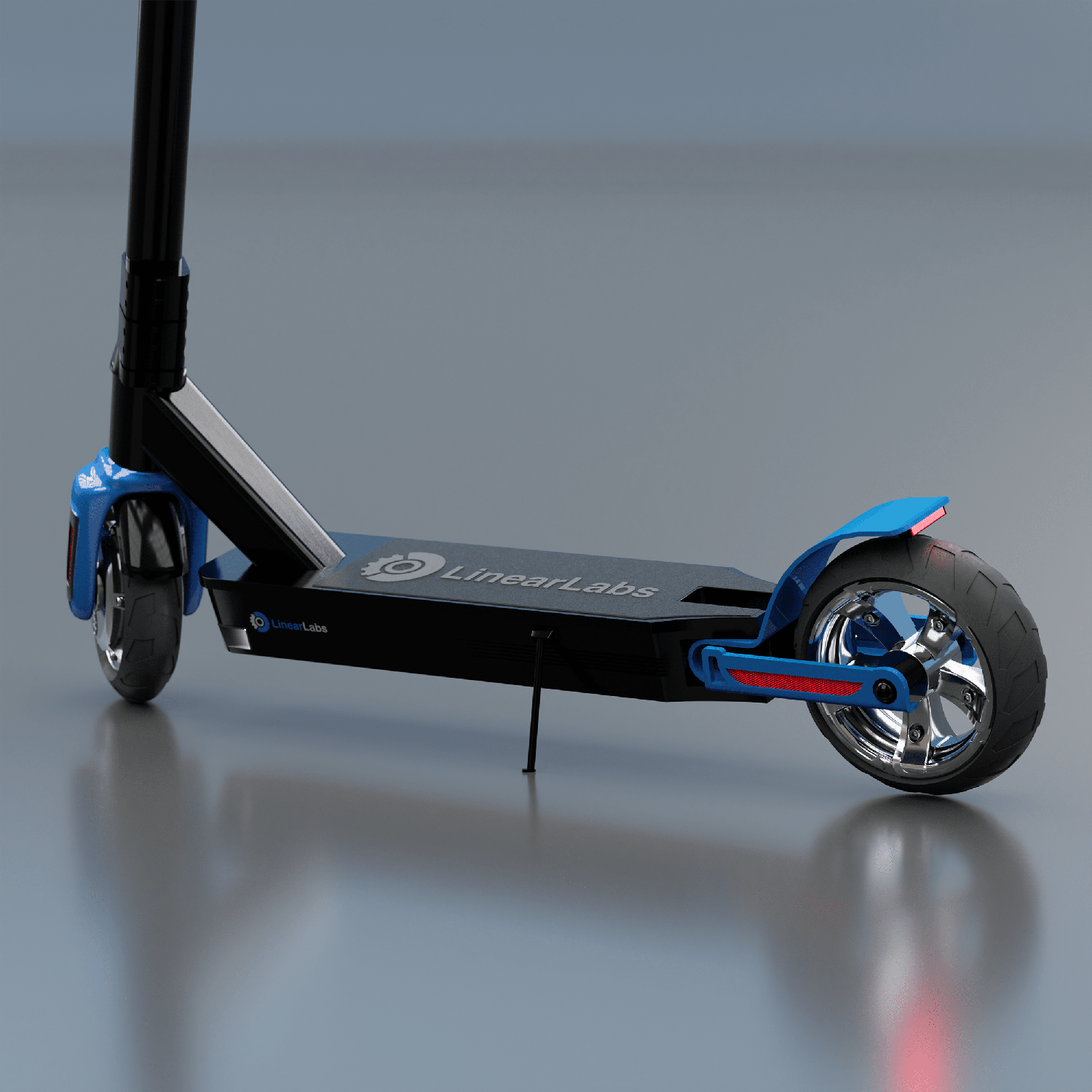

The Linear Labs HET Light Series motor systems are the most effective torque-producing motors in the world.

They have significant advantages over classic motors because the controller and software are designed together to improve torque by 2X and have a 30% increased efficiency.

The Problem

We know Light Electric Vehicles. If your business is eBikes, Motorcycles, Golf Carts, Utility Vehicles, Rideshare, Delivery Drones, Recreational Vehicles, or Logistics Robots then you know you need to get more action per charge. Every minute recharging is another minute you aren’t making money.

Our Solution

Linear Labs provides up to 2X more torque and range at higher efficiencies than our competitors while increasing durability, allowing for greater rider weight, and climbing those steep mountains.

We decreased system costs by reducing battery size and eliminating gearboxes, and providing up to a 100% increase in range.

Our motor systems consume up to 40% lower electricity and weigh less than the competition.

CONQUER THE URBAN JUNGLE

TURN LESS INTO MORE

The Problem

The global drive for increased efficiency, including the looming 2023 US Govt Standards is putting pressure on HVAC OEMs with no solution except for more expensive materials. Standard variable speed HVAC motors require expensive electronics and often utilize rare earth materials.

Our Solution

Linear Labs offers the highest efficiency motor 92% vs 84% (Top competition). We decreased system costs by using no variable frequency drive and rare earth metals and our adaptive supply chain means we’re able to source our components from anywhere in the world.

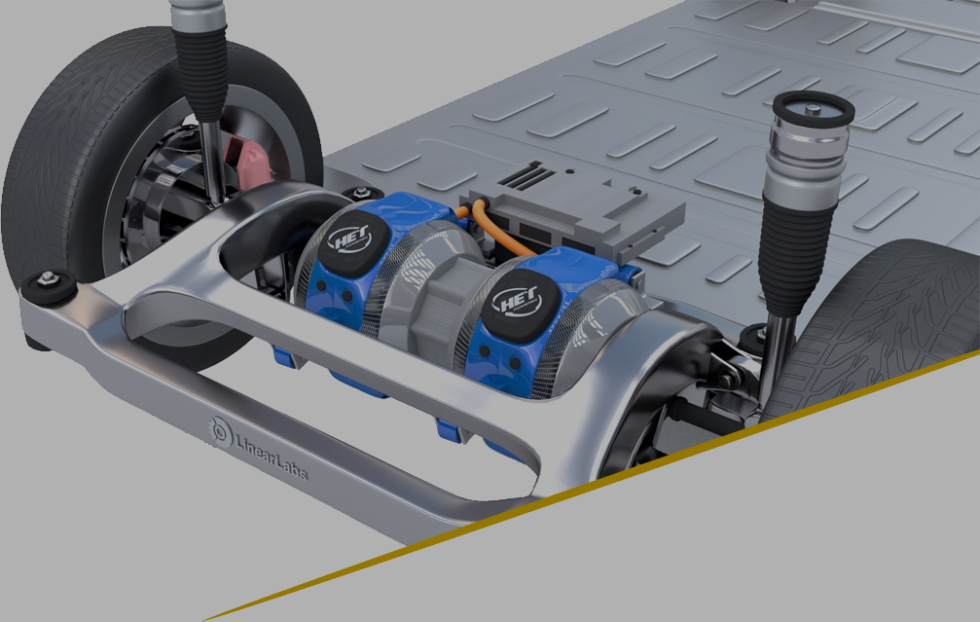

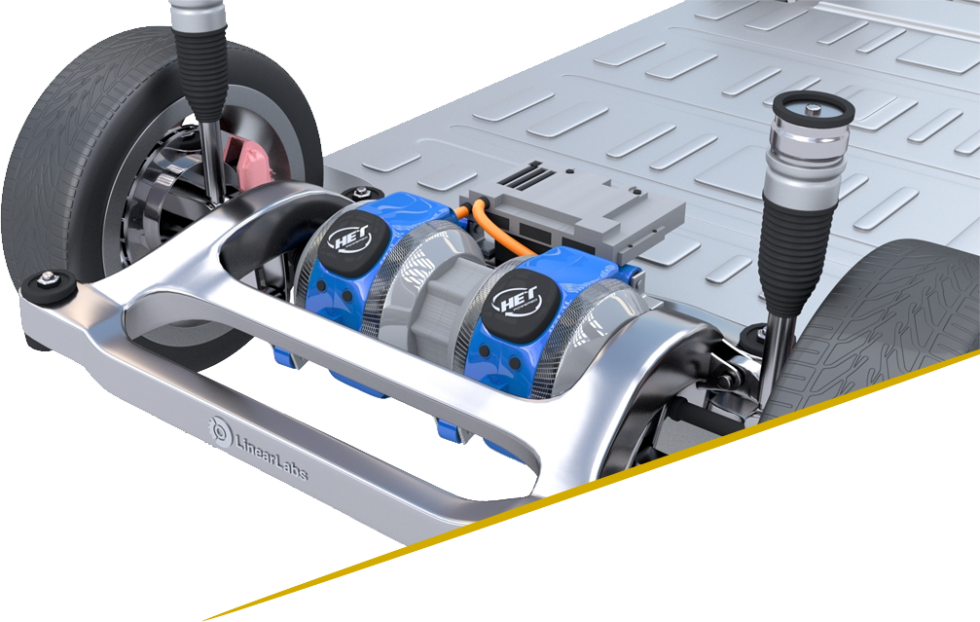

The Problem

If your business is Delivery and Garbage Trucks, Buses, 18 Wheeler Trucks, or Marine Applications, then you know you need to get more action per charge. Every minute recharging is another minute you aren’t making money.

Our Solution

Linear Labs motor systems provide up to 2X torque and increased range at higher efficiencies than our competitors while increasing higher payloads, longer hauls, and more durability.

We decreased system costs by reducing battery size and eliminating gearboxes, and providing up to a 100% increase in range.

Our motor systems consume up to 40% lower electricity and weigh less than the competition.

AMERICAN MUSCLE WITHOUT THE GAS

HOW TO COLLABORATE WITH US

Requirements

Answer our Engineering Requirements questionnaire telling us what you are doing and how you want your motor to perform.

Analysis

We sign a Motor Sizing Agreement and perform an electromagnetic analysis based on your Engineering Requirement document.

Agreement

Once the Motor Sizing Agreement is completed we enter into a Proof of Concept Development Agreement.

Execution

Linear Labs executes the POC Development Agreement and develops multi-stage prototypes as we move toward volume production of your motors and controllers.