Better Motor. Better Drive. Better Software.

76

PATENTS ISSUED OR PENDING

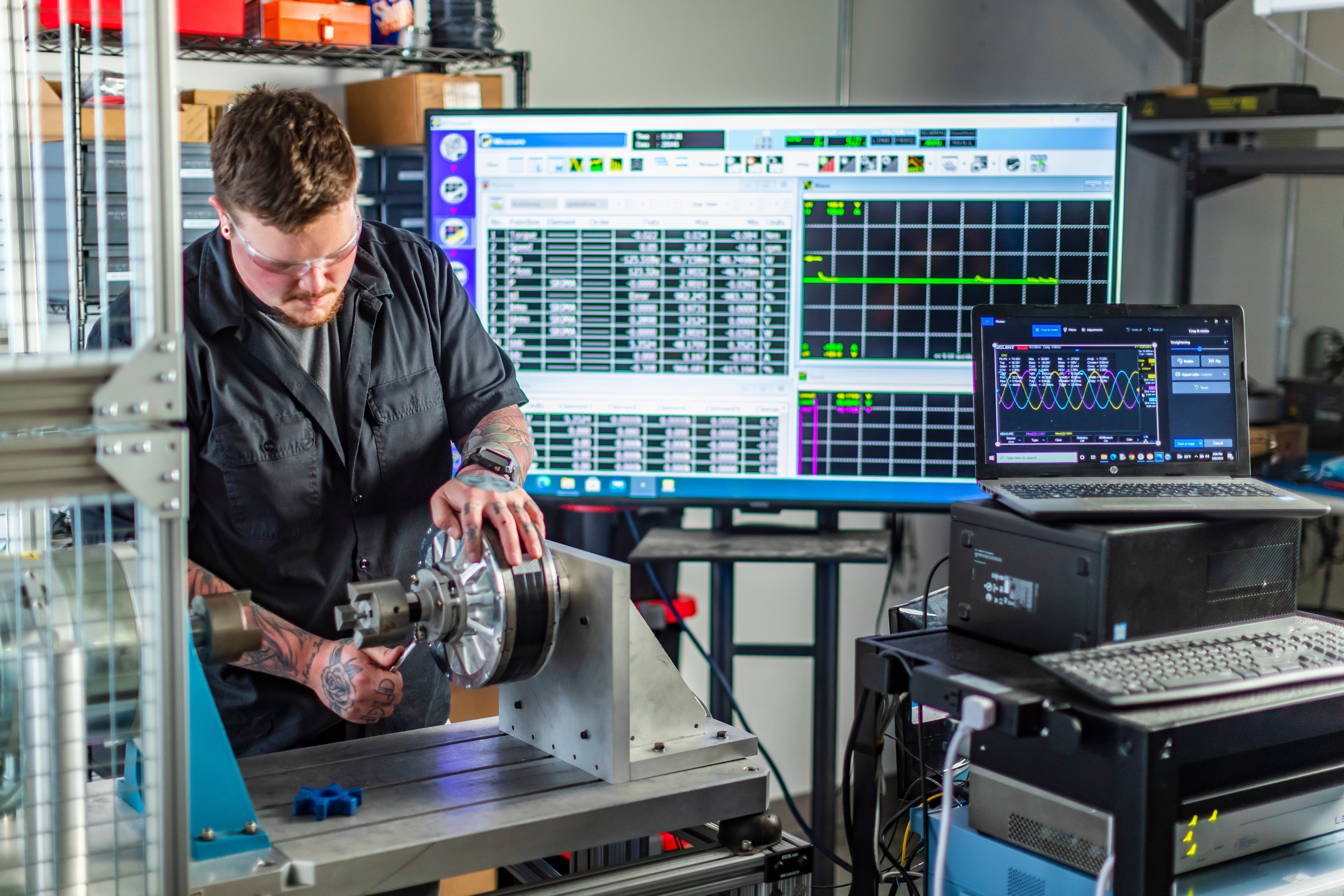

HIGHEST TORQUE MOTORS, SMARTEST CONTROLLERS, DYNAMIC SOFTWARE

The highest torque density motors in the world deliver performance per volume never seen until now.

- Proprietary Motor Topologies

- Highest Torque Motors

- Robust Patent Portfolio

- Superior Physics that Scales to Larger Sizes

- Dynamic Modularity

- Not Dependent on Rare Earth Metals

- High Manufacturability

Better Controllers

Intelligent controllers adjust to changing conditions in real-time, unlocking more performance and efficiency gains.

- Flexible and Modular Configuration

- Real-time adjustments

- Integrated & Tuned with Motor

- Compact, More Efficient

Better Software

By tightly tuning our controllers, our software provides intelligence and real-time decision-making of our motors outperforming motors on the market.

- Proprietary Algorithms

- Real-Time Decision Making

- Tightly tuned control of the motor

- Software Boost Performance

WANT OUR DATASHEETS?

HOW TO COLLABORATE WITH US

Requirements

Answer our Engineering Requirements questionnaire telling us what you are doing and how you want your motor to perform.

Analysis

We sign a Motor Sizing Agreement and perform an electromagnetic analysis based on your Engineering Requirement document.

Agreement

Once the Motor Sizing Agreement is completed we enter into a Proof of Concept Development Agreement.

Execution

Linear Labs executes the POC Development Agreement and develops multi-stage prototypes as we move toward volume production of your motors and controllers.